A High-resistance, Hard Wearing Specification for a New Overseas Recycling Project

With many of our clients now looking at recycling initiatives, we were excited to spec some of our hard grade steels for a project that needed a high level of wear resistance and toughness for a range of cutting and shredding processes.

Flexible Contractual Agreement Enables Short Lead Time Availability

In order to facilitate a hydraulic equipment project by one of our clients, we were approached by them to explore the supply of raw steel materials on short lead times of no greater than a week.

Hillfoot Technical Innovation: Bespoke Forged and Machined Parts for Key OEMs

Hillfoot demonstrated our ability to drive operational efficiencies through innovative design by developing a new way to produce and supply parts forged to nett shapes.

Engineering Steel Supply for the UK Defence Sector

Hillfoot’s long-established relationships with customers in the defence industry has enabled us to understand the complexity of the sector’s requirements and processes.

Not Just Forged Steel Bars

Hillfoot's established relationships with suppliers have helped us to reduce lead times, transport charges and material costs for customers using forged steel bars.

Supply Chain Improvement for Major First Tier Subcontractor

Due to the increasing demands of major OEMs to reduce inventory, improve lead times and reduce cost in the supply chain there was a need to investigate alternative methods of steel delivery.

Cost Savings Delivered for High-Volume Manufacturer

The Hillfoot commercial and technical teams combined to identify cost-saving opportunities in high-volume manufacturing plants, which delivered improved output and reduced tooling costs.

Supply Chain Management for the Hydraulics Industry

Hillfoot are key steel suppliers to the hydraulics industry. We supply blue chip hydraulic manufacturers and their sub-contract networks with raw material, semi-machined parts and fully-machined hydraulic assemblies.

A Commitment to Client Understanding

The ethos of Hillfoot is that all customers, however large or small their usage of steel may be, are equally important to the ongoing success of the business.

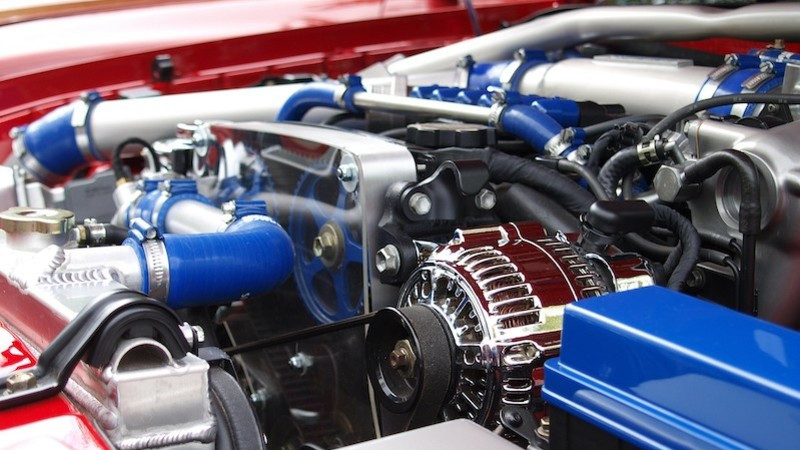

Metallurgical Re-engineering Delivers Cost Reduction on Engine Component

The Hillfoot technical team demonstrated their expertise in the motorsport field by delivering a significant cost saving on the production of a key engine component.

Extensive Metallurgic Advice Provided for Steel Specification

Sourcing a steel grade with increased properties in several critical locations within the material, enhanced strength and directional grain structure for optimum rail safety.

Forged Wheels and Axles Supplied in Modified Hardened Alloy for Defence Sector

Our client, a major name within the defence sector, required a large quantity of forged wheels and axles supplied in a highly modified hardened alloy material.

Refined Engineering in Motorsport Demands Superior Steel Grades

Not surprisingly, the motorsports sector demands specialist steel grades that can meet the very specific challenges of this high performance sport. When every thousandth of a second counts, and there is no margin for error, sourcing the right steel grade is critical.

Sourcing New Material Grades for a Prototype Hydraulic Rock Breaking Tool

Hillfoot assist with the material grade selection for a new rock breaking tool which was entering the prototype development stage.

Steel Grade Selection for Aviation Industry

How we identified cost reductions in raw materials without compromising design specifications such as superior cleanliness and fatigue resistance.